Motor Alignment Using Laser Shaft Alignment

1. Introduction

Accurate motor placement is essential for the proper operation of machinery and equipment in various industries. Improper equipment configuration can result in increased power consumption, significant mechanical failure, and decreased productivity. Fortunately, laser shaft alignment has proven to be a reliable and accurate method for motor alignment, assuring high performance and reducing downtime.

2. Understanding Motor Alignment

Motor alignment refers to the process of aligning the shaft of the motor with the shaft of the driven equipment being used to ensure complete parallel or coaxial alignment with the aim of eliminating any angular or offset differences, to enable effectively and efficiently transferring energy.

3. Importance of Motor Alignment

Accurate motor alignment offers many advantages, e.g.

- Energy efficiency: Proper configuration reduces energy consumption by reducing energy losses due to abnormalities.

- Reduced vibration and noise: Improper equipment alignment can cause excessive vibration and noise, causing more damage to components and reducing equipment life.

- Longer Bearing Life: Proper alignment reduces unnecessary stress on bearings, prevents premature failure and reduces maintenance costs.

- Improved machine performance: Aligned motors ensure smooth operation, reduce the risk of breakage and optimize overall machine performance.

4. Common issues caused by improper alignment

If the motors are out of alignment, various issues can arise e.g.

- Excessive heat generation: Improper alignment can cause overheating, increasing heat generation that can damage components and reduce device performance.

- And increased wear and tear: Bad alignment puts undue force and pressure on shafts and bearings, leading to accelerated wear and tear and potential for failure.

- Reduced power delivery: Disorganization hinders efficient power transfer, reducing machine performance and potentially delaying production.

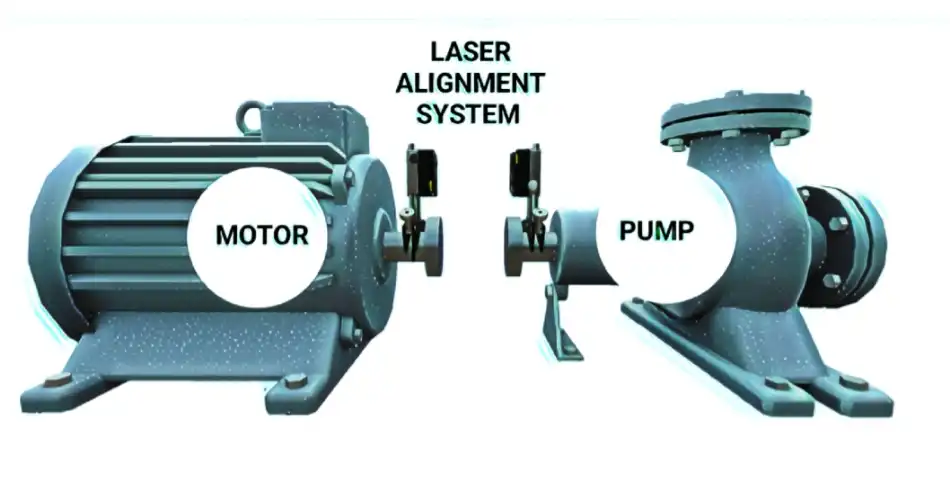

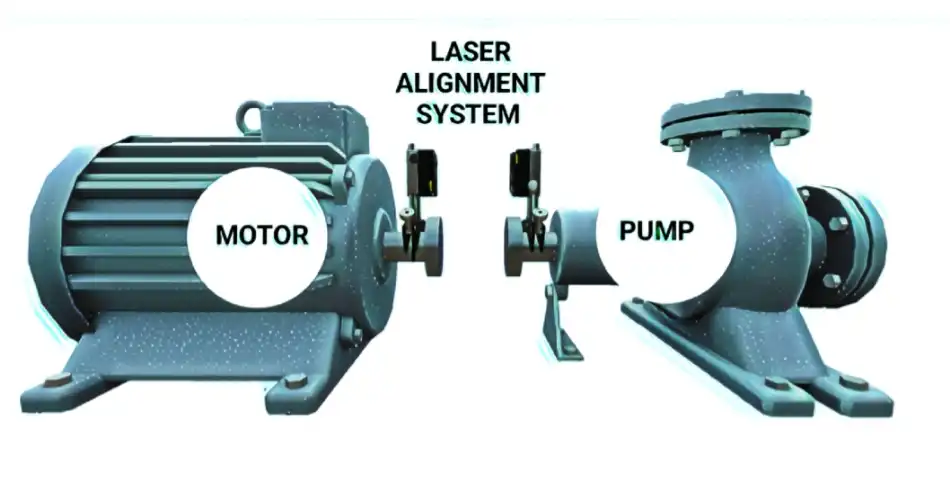

5. Introduction to laser shaft alignment

Laser shaft alignment is an accurate and comprehensive method of motor alignment. It uses laser technology to accurately measure and resolve discrepancies. This approach provides real-time data and eliminates manual calculations, resulting in a faster and more accurate matching process.

6. Advantages of laser shaft alignment

Laser shaft alignment offers many advantages over traditional alignment techniques:

- Accuracy: Laser alignment provides highly accurate alignment results, ensuring precise positioning of motors and control devices.

- Time efficiency: Laser alignment significantly reduces alignment time compared to manual methods, providing faster device placement and reducing downtime.

- Cost savings: Using laser technology with better alignment reduces energy consumption, minimizes equipment waste and reduces maintenance and repair costs.

7. Stepwise process of motor alignment using laser shaft alignment

Follow these steps to align the motor with laser shaft alignment.

7.1 Preparation for Alignment

- Assemble necessary tools and equipment, including laser alignment system, safety equipment, and any necessary supplies.

- Ensure that the equipment is switched off and properly cleaned before proceeding with the installation procedure.

7.2 Mounting of laser alignment equipment

- Connect the laser alignment equipment to the motorized equipment following manufacturer’s instructions.

- Position the tool carefully to maintain stability during alignment.

7.3 Taking Initial Measurements

- Install the laser detectors in appropriate locations on the shafts of the motor and machines shaft.

- With the angular offset misalignment data, follow the program instructions to take the first measurement.

7.4 Changes motor position

- Examine the measurement data for necessary motor changes.

- Gradually make small horizontal or vertical adjustments in the position of the motor, until the alignment parameters are within the specified tolerances.

7.5 Accuracy of alignment

- Remeasure the alignment using the laser system to ensure the adjustment achieves the desired alignment.

- Make further adjustments if necessary, and repeat the alignment and verification process until an optimal alignment is obtained.

7.6 Finalizing the Alignment

- Once the alignment is within acceptable parameters, lock the motor and driven equipment in their final positions.

- Double check the alignment measurements to ensure accuracy before finalizing the procedure.

7.7 Periodic Maintenance and Inspection

- Check the alignment of motors and controls regularly for any variations or discrepancies.

- Schedule periodic inspections and maintenance to ensure regular alignment and proper equipment performance.

8. Conclusion

Motor alignment using laser shaft alignment is key to optimal machine performance. By achieving precise alignment, businesses benefit from energy efficiency, extended machines life and increased productivity. Laser shaft alignment improves accuracy and ensuring smooth operation and reducing downtime.

9.Frequently Asked Questions

Q1 How frequently should the motor be checked for alignment?

The alignment of the motor have to be checked periodically, specially after major repairs or renovation, or if any signs and symptoms of misalignment are observed. Consistency checking out is recommended at the least as soon as 12 months.

Q2 Can laser shaft alignment be used for all types of motors?

Yes, laser shaft alignment can be used for motors such as electric motors, combustion engines and turbines.

Q3 Is laser shaft alignment more accurate than traditional alignment methods?

Yes, laser shaft alignment provides very accurate results compared to traditional alignment methods, as it eliminates manual calculations and provides real time data.

Q4 How does motor alignment using laser shaft alignment help save energy?

Accurate motor placement reduces power consumption by reducing power losses due to misalignment, resulting in energy efficiency and cost savings.